|

TB-GYK1224 5+1 COLORS MASTER FLEXO

|

|

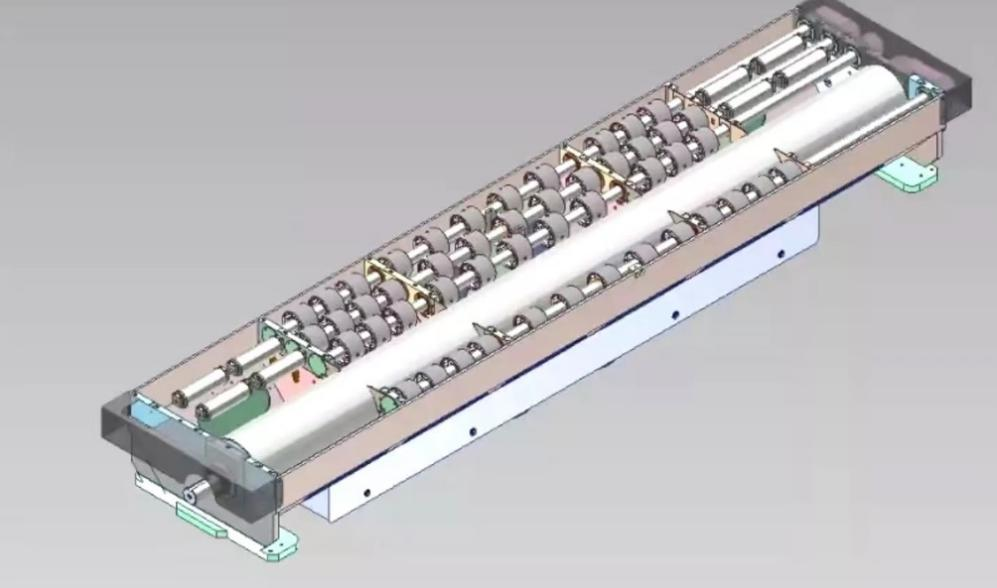

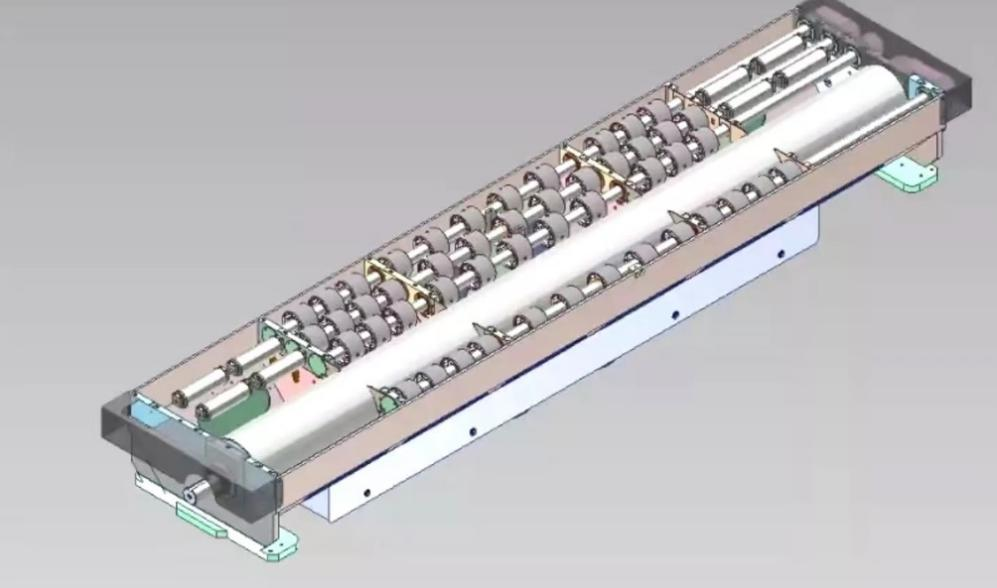

LEAD EDGE FEEDER UNIT

|

1 Unit

|

|

|

PRIINTING UNIT/COLOR

2 Ceramic Rollers

2 Dc. Blades

3 Metal Rollers

3 Rubber Rollers

|

5 Unit

|

|

|

IR DRYER UNIT -1

|

1 Unit

|

|

|

VARNISH UNIT

|

1 Unit

|

|

|

IR DRYER UNIT -2

|

1 Unit

|

|

|

DIE-CUTTING UNIT(SERVO)

|

1 Unit

|

|

|

Vibrating stacker unit

|

1 Unit

|

|

|

INDEPENDENT CONTROL CABINET

|

1 Unit

|

|

Specifications

● Adopt PLC touch screen control including the functions of indications of auto counting, speed, production, skip feeding and alarms;

● All transmission rollers are made of top quality steel processed through dynamic/static balance tests, chrome plating and polishing;

● China famous brand of transmission gears are adopted which are hardened and ground>60o Rockwell hardness; Using 40CR material, ensure the hardness and rigidity of the gear, ensure almost no wear after long-term use, make the power transmission of the machine stable and ensure the overprint accuracy.

● Main bearings from such as JAPAN NSK.

● Main electric components are purchased from the suppliers such as Germany SIEMENS.

● Spline free joint ring are employed to reduce center abrasion and remain precise registration for a long time;

● Auto zeroing and auto reset;

● Main motor start protection, main motor can not start when it is not locked to avoid error operation;

● Every unit of overall machine can be released automatically or separately, electric shifting and pneumatic locking with acoustic alarm in traveling to secure operators safety. The auto brake is able to stop machine running;

● Emergent protection: emergency switch is installed inside every unit to stop unit running inside machine for more security;

● The clearances of pull rollers, impression cylinder, rubber cylinder and anilox cylinder are all auto pneumatically locked.

● Specially made 7.5kW high pressure centrifugal fan, suction auxiliary feeding paper, smooth transmission, to ensure the smooth surface of the thin surface and lower quality of the smooth transmission of the board, the effect is obvious.

● All knives made of Tungsten and Carbide.

● Ink tanks made of stainless steel and thickness at least 4mm

Details Specifications:

LEAD EDGE FEEDER UNIT

● Adopt Servo motor separation drive, and V-belt connection.

● Adopt negative pressure suction flat sun feeding device, suit for any type flute board and any direction feeding, and ensure feeding accuracy.

● Feeding gap accurate adjustment, never damaged strength of the corrugate board

● Adopt pneumatic locking, with protection for overdrive, safe for operation.

● Corrugate board thickness: 2.5-10mm

(1) Lead edge vacuum roll feeder (Zero Pressure)

- The roller wheel type lead edge feeding vacuum feeding system ensure warped paperboard feeds accurately, skip feeding for large paperboard printing requirement.

- Automatic return to zero position.

- Motorized control of side guide position, operate by push bottom.

- Electric adjustment front/back baffle

- Motorized adjustment of feeding roll gap

- Continue feeding and skip feeding function.

- Pneumatic unit locking system, easy to operate.

a) Shandong QingYun Brand Feeding station

( Adopt U.S.A original Sun Wheel feeder drawing)

- Shandong Qingyun Brand feeding station, high production speed

- Skip feeding system

- Air blower adopts frequency converter to control air volume

- Durable feed drum and roller wheels

FUNCTION OF PRINTING DEPARTMENT

- Using vacuum adsorption conveying system, the wind box adopts linear guide rail orientation.

- Ceramic roll + Dc.blade

- Roller diameter: Φ405mm

- Plate roller:Φ405mm (Including printing plate diameter:410mm)

- High grade steel ceramic-plated, ground and laser engraving.

- Evenly distributed dot for evenly ink distribution.

- Advanced enclosed with ceramic anilox roller, scraping ink evenly, can increase distinctly quantity of monochrome branches and improve superimposition effect, realized high branches precision printing, high clear image ,the blade force uniform, 3 times to extend the service life.

- Anilox roller inking system, can printing for different requirement like coated paperboard, liner paper, high branches, large printing area.

- Phase fixing device, electromagnetic clutch automatic brake mechanism.

- Automatic ink circle system

- Plastic doctor blade. Minimum damage on anilox roller.

- Professional manufacturers to ensure the quality of the scraper system.

- Spray the Teflon material in the inner cavity of the scraper so that the ink does not bond to the cavity for easy cleaning.

- Double scraper form for easy dis-assembly.

- The gas propulsion method allows the scraper to smoothly fit the ceramic roller, and the scraping ink is more uniform.

- Insufficient automatic ink alarm device to avoid damage to the scraper and ceramic anilox roller.

- Scraper and ceramic anilox roller automatic cleaning system.

- Printing Unit(Standard top printing system)

- Press printing roller diameter:Φ175mm

- Automatic return to zero position.

- Automatic/ Motorized control of phase, digital display.

- Motorized control of printing roller transverse: 10 mm.

- Worm gear adjustment of roller gap

- Pneumatic unit locking system, easy to operate.

- Anilox roller operate by pneumatic

- Ceramic roller diameter: Φ210mm

Ceramic anilox roller with doctor blade

- The ceramic anilox roller is using with a semi-closed doctor blade

- The doctor blade system uses American technology, beautifully printed, and ultra low loss

- Prevent evaporation from being more environmentally friendly

- The inking contact adjustment of the anilox roller is a pneumatic pressure-pressing action, and the protection device is automatically lifted when the air is stopped. At the same time, the transmission gear center is unchanged

- Micro-adjustment of the gap between the anilox roller and the plate wheel

- Automatic sensor detection ink system, including warning lights and alarm bells

- The ink pump is a double way diaphragm type pneumatic pump, which can recover the water in the pump and the water in the tube with filter and ink circulation system

- The cartridge is quickly disassembled and the inner surface is sprayed with Teflon to improve cleaning efficiency

- Closed cover and recycling ink tank device, easy to clean and leak-proof design

Doctor blade

- Professional manufacturer to ensure the quality of the scraper system.

- Spray the Teflon material in the inner cavity of the blade , the ink does not bond to the cavity for easy cleaning.

- Double scraper form for easy dis-assembly.

- Hydraulic push mode, allowing the scraper to smoothly fit the ceramic roller, making the ink evener.

- Insufficient automatic alarm device to avoid damage to the scraper and ceramic anilox roller.

- Scraper and ceramic anilox roller automatic cleaning system

Ink supply system

- Pneumatic diaphragm pump, simple operation, easy maintenance, stable ink supply.

- Circular pneumatic ink application, automatic cleaning of ink.

- Filter screen filters impurities to ensure printing quality.

- Phase adjustment mechanism: All phase adjustments use this mechanism

- Unique planetary gear structure, 360-degree adjustment, both running and stopping.

- Print phase adjustment digital display screen display.

- Automatically reset the system after scrubbing the printing plate.

- Phase fixed system:

- Electromagnetic clutch brake type braking device. The clutch or phase adjustment of the unit keeps the original meshing point of the transmission gear unchanged.

- Ceramic screen roller in printing department is equipped with scraper

Phase adjustment mechanism

- Planetary gear construction.

- Printing phase adopts PLC, touch screen control and electric digital 360 ° adjustment (can be adjusted during running and stopping)

- Horizontal position, electrical adjust the distance. Total: 20mm.

- The printing roller adopts frequency converter to adjust the phase, return to zero and adjust the printing speed, and the adjustment accuracy is high.

- Printing phase fixture

- Pneumatic brake mechanism.

- When the machine operate or adjusts the phase, the brake mechanism restricts the rotation of the machine and maintains the fixed position of the original gear position

1ST IR Drying unit

Infrared drying system

● Infrared heating system, the temperature rise is fast and stable. The heating power is about 20kw.

- Temperature constant temperature control, segment heating, saving electric heating power.

- Temperature alarm, automatic alarm when the temperature exceeds the standard, safe and reliable.

- Powerful fan circulation makes the drying speed more rapid.

- Drying the box body to adjust the lift, convenient to install and replace the lamp tube, and convenient to adjust the drying effect.

Oil Coating Unit

Coating roller

- Select high-quality steel, professional production, dynamic balance test and fine grinding, the surface of the roller is engraved with latitude and longitude lines, and the plate is quicker.

- The surface is hard chrome plated for durability.

- There is a hanging slot, 10mm hanging strip with ratchet fixed coil shaft, convenient for hanging version.

- It is equipped with a foot switch, which controls the Roller to be positive and reverse, which is convenient for hanging and unloading.

- Touch screen control or electric control 360 degrees positive and negative adjustment of the printing roller, using inverter two-speed control. The man-machine interface is set to automatically locate.

- The touch screen control or button controls the axial adjustment of the printing roller with a maximum movement of ±10mm. The man-machine interface is set to automatically locate

Wind suction box

- The embossing roller is made of high-quality seamless steel pipe, with surface finish and hard chrome plating.

- After the embossing roller is statically balanced, it is corrected by dynamic balance and runs smoothly.

- Multiple sets of roller arrangement to ensure smooth and smooth paper feeding.

- The suction box lifting gap adopts electric adjustment/digital control, and the man-machine interface is set to automatically position.

- The vacuum adsorption box fan is controlled by frequency converter, and the air volume is adjustable

Anilox roll

- Anilox roller gap adjustment Taiwan large transmission ratio geared motor.

- The anilox roller gap adjustment adopts electric adjustment, the touch screen displays the adjustment amount, and the man-machine interface is set to automatically locate

- Phase adjustment mechanism

- Print phase planetary wheel differential adjustment.

- The touch screen controls the printing phase to adjust 360 degrees, and can be adjusted (running, stopping).

- The axial displacement of the plate roller is electrically adjusted, and the touch screen displays the adjustment amount. Adjustment amount ± 10mm is convenient for the versio

2nd IR Drying unit

- Infrared heating system, the temperature rise is fast and stable. The heating power is about 45 kw.

- Temperature constant temperature control, segment heating, saving electric heating power.

- Temperature alarm, automatic alarm when the temperature exceeds the standard, safe and reliable.

- Powerful fan circulation makes the drying speed more rapid.

- Drying the box body to adjust the lift, convenient to install and replace the lamp tube, and convenient to adjust the drying effect.

DIE CUTTING (Independent motor drive)

- The roller is made of hard chrome plated on the surface, material is high-quality steel, After dynamic.

- Balance correction, to increase its operating stability and reliability.

- Die roller and soft roller made by international standard size, die roller diameter: 360mm, plus wooden die diameter: 410mm, soft roll diameter is 378mm (excellent rubber sleeve outside diameter 397 mm), can be purchase the wooden die and rubber anywhere.

- Adjust the gap between the die cutter roller and the rubber roller by electrical adjustment.

- The phase of the die-cutting roller adopts a three-planetary structure, which has high precision and large bearing capacity. The stop and operation can be adjusted by electric digital 360°.

- When the paper feed stop, the soft roll rises automatically, reduce the wear of the soft roll.

- The rubber is made of polyurethane felt cover Germany Dipair brand, which can achieve 100% cutting rate. The incision is smooth. The replacement order of the rubber pad shall be based on the loading and unloading operation manual of the rubber pad.

- The rubber pad roller adopts the mechanical cam type left and right movement (30mm) device, each knife is in different positions, effectively extending the service life of the felt sleeve.

- Die cutting upper and lower rollers have different diameters, but the two rollers have the same linear velocity. It can control the infinitely non-circulating work of the die cutter in the circumferential direction, making the wear of the rubber sleeve more uniform.

- With line speed compensation device, when the soft roller diameter changes, the line speed automatic compensation device automatically track compensation, without manual adjust the speed, to ensure that the size of each batch of cardboard boxes die-cutting is exactly the same, while greatly extending the felt and knife mold life.

- The soft roll automatic repair device can repair the worn felt cover several times. The repaired felt cover is smooth and clean, and maintains the same performance as the new felt cover. Greatly increase the reusability of felt mats.

- Die cutting lower cylinder equip ring slotting knife, the lower roller can electrical move left and right ±10mm.

- Die cutting unit have control panel for paper feed opening/closing and host electric button, with multi-point adjustment operation function.

Vibrating stacker unit

Stacker introduction

- This part is mainly suitable for chip cleaning after processing by the circular die cutting machine, which effectively reduces the waste of human resources in manual waste cleaning. As a result, the carton processing efficiency is higher and the technology is more perfect.

- This machine is equipped with pneumatic lift to provide enough space for the front machine to change, adjust, and maintain. This machine is equipped with a pneumatic brake function, which makes the machine and the front machine more stable during normal operation.

- The waste cleaning machine adopts inverter, high-speed control system of inverter motor, inverter adopts domestic famous brand, inverter motor adopts Hengshui Yongshun brand, motor is equipped with independent fan cooling configuration, main motor power paper is 3.0KW, vibration motor power is 1.5 KW, also equipped with side output function, side output function is controlled by cycloid motor, power is about 0.37KW.

- The side output function is a special configuration of the waste cleaning machine designed by our factory in order to reduce the time and labor waste caused by cleaning debris. This configuration greatly saves time and labor for cleaning debris and working area hygiene. Meet the standards of time, labor and hygiene.

- This machine adopts 30MM thick middle plate as the wall plate, which makes the machine run more smoothly. 6.The round belt of this machine is made of high-quality polyurethane material and is made by domestic advanced casters. It has the advantages of anti-stretch, abrasion resistance, softness and good elasticity.

Paper receiving arm

- The machine has manual and automatic operation.

- Attach the belt of the paper arm, adjust the tightness separately, and not be limited by the length of the belt. The speed of folding paper is adjusted arbitrarily in a certain range

Platform lifting

- Strong chain drive.

- 。

- The stack height is 1600mm

- 1600mm

- Platform lift drive motor with brake function, the platform can maintain a fixed position, will not decline

Paper baffle

- The pressure action of the paper tray, when the board is piled up to the predetermined height, the paper tray is automatically extended to hold the cardboard.

- The rear baffle position is manually adjusted.

- Plane wrinkle belts to prevent the cardboard from slipping

Material selection:

- 20Cr alloy steel material, after grinding high frequency processing.

- Six-level accuracy, operation smoothly, low noise, hardness HRC58-62, long life, wear small, can guarantee the long-term accuracy of the printing color.

- The phase gear is made of 20Cr alloy steel material, which is made of quenched and tempered, high-precision grinding teeth, hardness HRC58-62.

- Planetary gears are made of 20CrMnTi. After quenching, they are quenched and tempered and treated with carburized gears to quench HRC58-62.

- The thickness of the machine wall is70mm solid casting, which is processed by quenching and tempering to make the machine run smoothly and the wall plate is not deformed.

- The connecting bar is made of 250mm square steel welded, so that the machine is stable and does not vibrate.

- Adopt cast iron track walking track, walking stable.

- Adjust the gap by double-click to adjust the pressure.

- Adopt double-head diaphragm pump.

- The transmission part adopts the cross-slider with no gap transmission, the gear thickness is 60- 80mm thick, and it is made of quenched and tempered, high-frequency quenched and made of 40- chrome steel.

Spare parts list

|

NO.

|

Name

|

Unit

|

QTY

|

Details

|

|

1

|

Diaphragm pump

|

Piece

|

1

|

|

|

2

|

Transverse copper

|

Piece

|

10

|

|

|

3

|

electromagnetic valve

|

Piece

|

4

|

|

|

4

|

Tool

|

Piece

|

1

|

|

|

5

|

Tool

|

Set

|

1

|

Plus 12 Hexgon

|

|

6

|

8# air pipe

|

Meter

|

50

|

|

|

7

|

air connection

|

Piece

|

10

|

|

|

8

|

Straight air joint

|

Piece

|

10

|

|

|

9

|

air nose

|

Piece

|

1

|

|

|

10

|

M10 screw

|

Piece

|

4

|

|

|

11

|

Hexagon screw

|

Piece

|

4

|

|

|

12

|

Hexagon screw

|

Piece

|

5

|

|

|

13

|

Specid screw

|

Piece

|

5

|

|

|

14

|

Hexagon screw

|

Piece

|

4

|

|

|

15

|

Flat washer

|

Piece

|

10

|

|

|

16

|

Spring washer

|

Piece

|

10

|

|

|

17

|

Diemods screw

|

Piece

|

30

|

|

|

18

|

Lead edge feeder rubber wheel

|

Piece

|

10

|

|

|

19

|

printing die film

|

Piece

|

2

|

|

Printing machine main parameter

|

No.

|

Parameter

|

Unit

|

Details

|

|

1

|

Machine size(inner side)

|

mm

|

2600

|

|

2

|

Max. Design speed

|

pieces/min

|

230

|

|

3

|

Economical speed

|

pieces/min

|

200

|

|

4

|

Max. Paper Feeding size

|

mm

|

1200x2400

|

|

5

|

Min. Paper feeding size

|

mm

|

350x550

|

|

6

|

Max. Printing size

|

mm

|

1200x2200

|

|

7

|

Skip paper feeding size

|

mm

|

1240x2200

|

|

8

|

Standard print plate thickness

(Plus cushion)

|

mm

|

4.8-7.2

|

|

9

|

Paperboard thickness

|

mm

|

2-10

|

|

10

|

Diameter of Printing Roller

(Including Printing Plate)

|

mm

|

405

|

|

11

|

Printing registration precision

|

mm

|

≤±0.25mm

|

|

11

|

Die cutting precision

|

mm

|

≤±1.5mm

|

|

12

|

The thickness of wall

|

mm

|

60

|

|

13

|

Print roller axial direction adjustment

|

mm

|

±10

|

|

14

|

Die molds cylinder axial direction adjustment

|

mm

|

±10

|

Main Parts and origin

|

No.

|

Name

|

Picture

|

Function

|

Brand

|

Note.

|

|

1

|

Lead edge feeder system

|

|

|

Taiwan technology

|

|

|

2

|

Frequency conv erter

|

|

22kw

|

Delta (Taiwan)

|

|

|

3

|

Inspect parts

|

|

|

Siemens. German

|

|

|

4

|

Electrical parts

|

|

|

Schneider (France)

|

|

|

5

|

PLC

|

|

|

Delta(Taiwan)

|

|

|

6

|

Encoder

|

|

|

Shanghai

|

|

|

7

|

Touch screen

|

|

10 Main screen: 10 inch

Other: 7 inch

|

Siemens. German

|

|

|

9

|

Button

|

|

|

Schneider (France)

|

|

|

10

|

Main motor

|

|

22kw

|

Yongshun China

|

variable frequenc y motor

|

|

11

|

Fan motor

|

|

7.5kw

|

Yongshun China

|

|

|

12

|

gear reducer

|

|

0.18kw 0.37kw

|

Zhejiang

|

Phase repair side baffle.

|

|

13

|

Ink Distribution motor

|

|

400w

|

Dongbang,

|

|

|

14

|

Split motor

|

|

1.5KW

|

Shan Dong

|

|

|

15

|

The main body wallboard

|

|

Thickness 70mm

|

Precision cast iron

|

Japan Mitsubishi five-sided machining center

processing.

|

|

16

|

Transmission gear

|

|

Thickness 60-80mm

|

20Cr

|

High precision grinding teeth.

|

|

17

|

Printing roller

|

|

ɸ390.6mm

|

45# steel rolling welding, computer dynamic balance correction, grinding and hard chromium plating.

|

45#,,

|

|

18

|

Ceramic roller

|

|

∮213mm

|

HAILI

|

Dynamic balance correction

|

|

19

|

Doctor blade system

|

|

|

Guangzhou

|

|

|

20

|

Bottom printing roller

|

|

ɸ154.3mm

|

45# 45 seamless steel tube

|

,Dynamic balance correction,grindin

g and hard chromium plating.

|

|

21

|

Bearing

|

|

|

NSK. HRB .UC

|

|

|

22

|

Pneumatic parts

|

|

|

Zhejiang Tianao

|

|

|

23

|

Pneumatic diaphragm pump.

|

|

|

Wuhan jinchangjiang

|

|

|

24

|

Free link

|

|

|

Xianyang

|

|

|

25

|

Overrunning clutch

|

|

|

Xianyang

|

|

|

26

|

Optimal force glue cushion

|

|

Width: 250mm

|

Dipack German

|

|

Printing samples