Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 0%

| Model No.: MY-1300/1500/1650 | Place of Origin: China |

Automatic Die-cutting and Creasing Machine

(manual-automatic type)

Function and characteristics

● The machine has manual and automatic motion state models. When the paper quality is poor, the manual model can be used and it can be switched. When using a manual model, you can free up space and be suitable for operation.

● The paper feed unit of the machine is an independent system. It can be connected with die cutting machines of other manufacturers. The machine is equipped with a replacement part that can remove waste from the three edges and holes in the middle of the die-cut sheet.

● This machine has a powerful four-suction and four-feed paper feeder, which can adjust the suction angle through paper deformation and blow the paper separating device to facilitate paper separation.

● It has an overload protection mechanism to achieve accidental overload, and actively separates the die-cutting board frame, which can effectively prevent the die-cutting board from sagging and replacement.

● The main chain (Germany) adopts heavy-duty and advanced transmission chain, with minimal production error, high tensile strength and good wear resistance.

● The electrical control system is controlled by PLC and is equipped with various safety protection devices. When a fault occurs, it can give out sound and light alarm and automatically shut down, which truly guarantees the safety of man and machine.

● The timing and quantitative automatic oil supply system can ensure sufficient lubrication for other moving parts of the machine and long replacement.

Parts Description

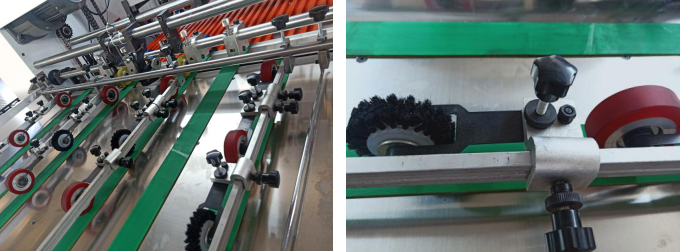

01. Feeding part

● Use high-quality steel to install and fix firmly, easy to operate.

● It is possible to install die-cut paper under the code paper during normal paper feed work. There is no need to waste time caused by the code paper link.

● The machine has manual and automatic motion state models. When the paper quality is poor, the manual model can be used and it is easy to switch.

02. Feeding table

● It has the opposite optoelectronic properties. It can automatically lift and manually adjust the lifting distance.

● It can also adjust the photoelectric position according to whether the paper is bent to ensure that the leading edge of the continuous paper is flush with the paper feed baffle.

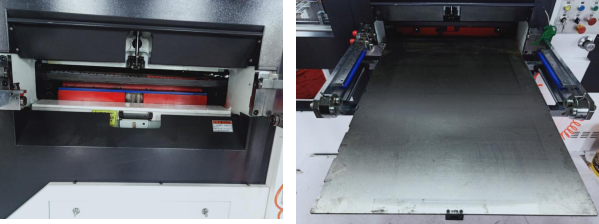

03. Diecutting part and Delivery system

● The maximum die-cutting pressure of the host is 300N/cm2, which can ensure that the product with the largest width can be cut through and the indentation is full.

● The main engine adopts worm gear transmission, with large torque, stable and reliable transmission, low noise and long service life.

● The main wall panel is made of high-quality ductile iron, and the upper platform and movable platform are also made of high-quality ductile iron to ensure its resistance to compression, deformation and shock absorption.

● And equipped with a forced lubricating oil pump to achieve full oil at each lubrication point. The die cutter board is easy to install, easy to pull out, and the time to replace the board is short.

● The main chain (Germany) adopts a heavy-duty high-precision transmission chain with small yield error, high tensile strength and wear resistance.

● The overload protection mechanism can realize accidental overload, and the active separation of the die-cutting board frame can effectively prevent the die-cutting board from sagging and falling.

04. Stacker part

Automatic counting and alarm for the scattered board. Automatic paper dropping, automatic warning and paper dropping is full.

According to the product size, adjust the left and right, front and back of the cardboard to achieve the paper output level

05. Electric system

The electronic control system is controlled by PLC and equipped with various safety protection devices. When a fault occurs, an audible and visual alarm will be issued, and the machine will automatically stop to ensure the safety of people and machines.

Origin details of main purchased parts

Electrical parts

|

Name |

Picture |

Brand |

Model |

|

Frequency converter |

|

Fuji, Japan |

|

|

PLC Control PLC |

|

Mitsubishi, Japan |

|

|

Contactor |

|

Fuji, Japan |

|

|

Operation button |

|

Schneider, France |

|

|

Photoelectric sensor |

|

Omron, Germany |

|

|

touch screen |

|

Taiwan Taida |

|

|

Circuit breaker |

|

LS Korea LS |

D40 D16 D6 |

|

Alarm lamp |

|

Korea q-light |

|

Other parts

|

Other parts |

Picture |

Brand/texture of material |

Model |

|

Toothed chain |

|

Imported from Germany |

RS2060 |

|

Dentition |

|

Superhard alloy aluminum |

|

|

Other bearings |

|

NSK Japan NSK |

|

|

Die cut steel plate |

|

65 manganese steel Taiwan |

|

|

Intermittent mechanism |

|

Taiwan |

200° |

|

Feeding and receiving motor |

|

Taiwan |

750W |

|

Main motor |

|

Siemens, Germany |

11KW |

|

principal axis |

|

|

High frequency quenching |

|

Air clutch |

|

Shanghai Yuyi |

|

|

main bearing |

|

Sweden |

|

|

Pneumatic valve |

|

Adek Taiwan |

|

|

Grease pump |

|

Taiwan |

|

|

Grease pump |

|

Tianjin |

|

| air conditioner |  |

Shanghai |

Main paramaters

|

Item |

Parameters |

|

Model |

MY-1300 |

|

Max paper transmitting size (mm) |

1300X930 |

|

Min paper transmitting size(mm) |

500X450 |

|

Max die cutting size(mm) |

1280X910 |

|

Min gripper size(mm) |

8mm |

|

Max die cutting pressure |

350N/cm² |

|

Max die cutting speed |

5500 sheets/h |

|

Max feeding pile height |

1200mm |

|

Min feeding pile height |

1200mm |

|

Main motor power |

11kw |

|

Total weight |

17T |

|

Overall size |

6500*2300*2300 |