Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 0%

| Model No.: MY-1300/1500/1650 | Place of Origin: China |

MY 1300/1500/1650 automatic die-cutting and creasing machine with leading edge feeding (full waste cleaning/half waste cleaning)

Function and characteristics

● The use of the patented lead edge feeding structure can effectively prevent and reduce the damage to the paper printing surface.

● This machine is mainly used for corrugated paper of no less than 3mm.

● The main chain (Germany) adopts heavy load and high precision transmission chain, with very small production error, high tensile strength and wear resistance.

● There are two ways of receiving paper, such as towing board and trolley, which greatly improve the working efficiency. It has photoelectric detection device, safe and reliable, and ensure the fast and steady receiving of paper.

● It has overload protection mechanism, to achieve accidental overload, active separation of the die - cutting board frame can effectively prevent the die - cutting board sagging and fall off.

● Pneumatic lock plate mechanism adopts imported cylinder, stable performance, convenient and fast operation.

● The electric control system is controlled by PLC and equipped with various safety protection devices, which can give audible and visual alarm in case of failure and shut down automatically, truly guaranteeing the man-machine safety.

● The timing and quantitative automatic oil supply system can ensure the full lubrication of other moving parts of the machine and have long service life.

● Stripping unit (optional).

Parts Description

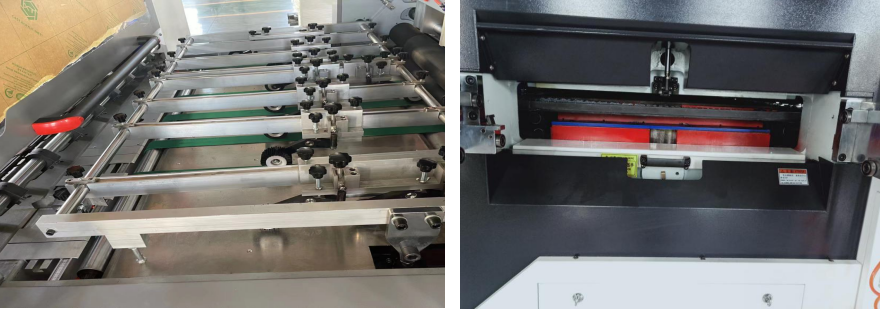

01. Feeding part

● Use high quality steel to install and fix firmly, easy to operate.

● Can be in the normal continuation of paper work, code installed the next die-cutting paper, there is no need to cause code paper link caused by the waste of time.

● The use of the patented preedge feed structure can effectively prevent and reduce the damage to the paper printing surface.

● The leading edge feed adopts vacuum adsorption feed and is driven by domestic famous brand servo motor.

● There are two feeding methods, from whiteboard paper to 7mm corrugated paper, which can be used to meet a variety of paper sizes and a wide range.

● Equipped with counter photoelectric, can automatically rise and fall, but also according to whether the paper is bent, adjust the photoelectric position, in order to ensure that the feeding front and the paper baffle flat.

02. Feeding table

● It is equipped with opposite photoelectricity. It can automatically lift and manually adjust the lifting distance.

● It can also adjust the photoelectric position according to whether the paper is bent or not, so as to ensure that the front edge of the continued paper is flush with the feed baffle.

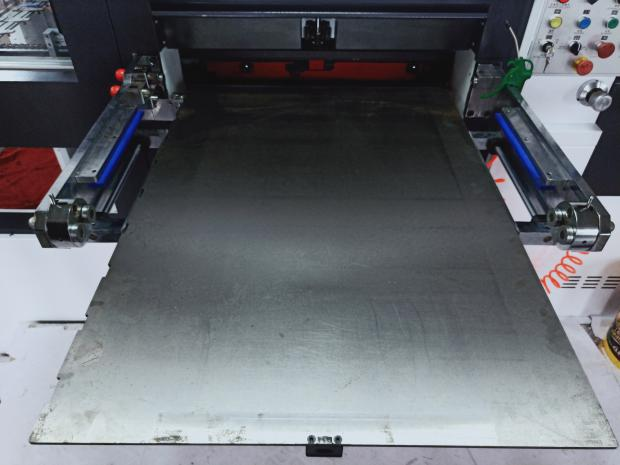

03. Diecutting part and Delivery system

● The maximum die-cutting pressure of the main machine is 350N/C㎡.

● The main engine is driven by worm wheel and worm, with large torque, stable and reliable transmission, low noise and long service life.

● The main wall panel is made of high quality ductile iron, and the upper platform and the moving platform are also made of high quality ductile iron, so as to ensure its ability to resist compression, deformation and vibration.

● And equipped with a forced lubricating oil pump, the realization of each lubrication point oil quantity. Die - cutting knife version easy installation, extraction freely, short version time.

(the bearings and electrical parts are selected from well-known foreign brands)

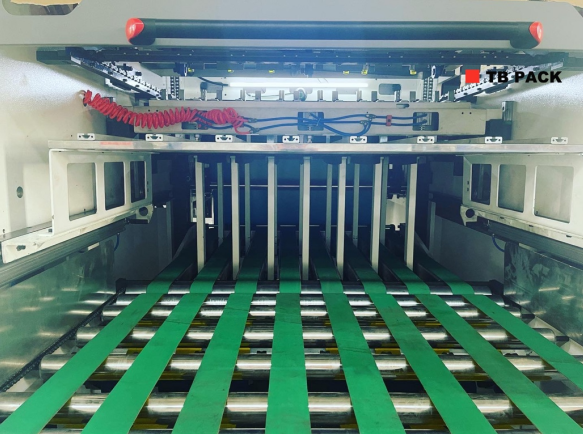

04. Stacker part

Automatic counting, scattered board alarm. Automatic drop of paper receiving, automatic warning and falling of paper receiving full.

According to the size of the product, adjust the left and right and front and back of the paperboard to achieve the paper receiving level.

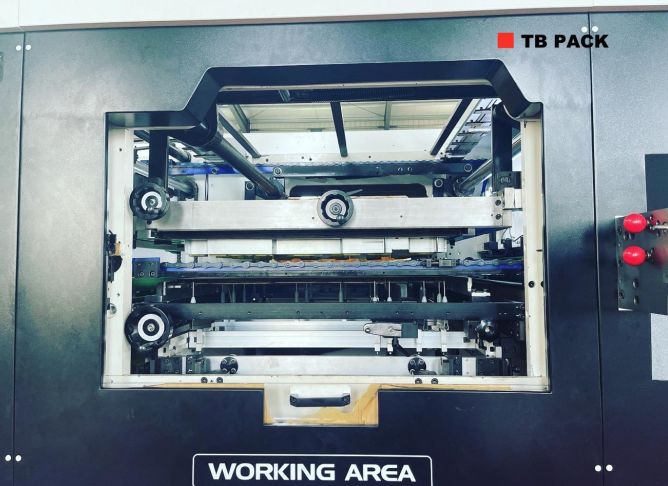

05. Stripping part (optional)

● The full waste cleaning template adopts the central positioning system, automatic clamping, quick and convenient to the version; The waste removal frame adopts motor control lifting device; It can automatically remove the three and four sides and the intermediate waste, so as to ensure a clean and efficient production.

● The semi-waste cleaning system can be used to clean up the required part of the paperboard to ensure that the waste cleaning is clean and efficient.

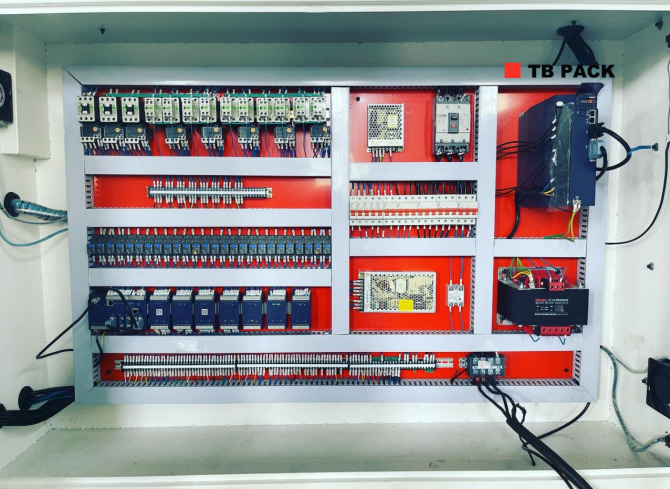

06. Electric system

The electronic control system is controlled by PLC and equipped with various safety protection devices. When the fault occurs, the sound and light alarm will be given and the machine will stop automatically to ensure the safety of man and machine.

Origin details of main purchased parts

01. Electrical parts

|

Name |

Picture |

Brand |

Model |

|

Frequency converter |

|

Fuji, Japan |

|

|

PLC Control PLC |

|

Mitsubishi, Japan |

|

|

Contactor |

|

Fuji, Japan |

|

|

Operation button |

|

Schneider, France |

|

|

Photoelectric sensor |

|

Omron, Germany |

|

|

touch screen |

|

Taiwan Taida |

|

|

Circuit breaker |

|

LS Korea LS |

D40 D16 D6 |

|

Alarm lamp |

|

Korea q-light |

|

Other parts

|

Other parts |

Picture |

Brand/texture of material |

Model |

|

Toothed chain |

|

Imported from Germany |

RS2060 |

|

Dentition |

|

Superhard alloy aluminum |

|

|

Other bearings |

|

NSK Japan NSK |

|

|

Die cut steel plate |

|

65 manganese steel Taiwan |

|

|

Intermittent mechanism |

|

Taiwan |

200° |

|

Feeding and receiving motor |

|

Taiwan |

750W |

|

Main motor |

|

Siemens, Germany |

11KW |

|

principal axis |

|

|

High frequency quenching |

|

Air clutch |

|

Shanghai Yuyi |

|

|

main bearing |

|

Sweden |

|

|

Pneumatic valve |

|

Adek Taiwan |

|

|

Grease pump |

|

Taiwan |

|

|

Grease pump |

|

Tianjin |

|

Main paramaters

|

Model |

MY1300 |

MY1500 |

MY1650 |

|

The maximum feed size |

1300×930 |

1500×1100 |

1650x1200 |

|

Minimum feed size |

450×400 |

500×450 |

550×500 |

|

Maximum die cutting size |

1280×910 |

1480×1080 |

1630×1180 |

|

Die cutting accuracy |

≤±0.50mm |

≤±0.50mm |

≤±0.50mm |

|

mechanical speed |

5500S/H |

5500S/H |

5000S/H |

|

working pressure |

350T |

350T |

350T |

|

Main motol power |

11kw |

11kw |

15kw |

|

total power |

38kw |

38kw |

38kw |

|

The mechanical net size |

9100×2300×2300 |

11000×2450×2300 |

13000×2600×2300 |

|

machine weight |

17T |

19T |

22T |